India’s small holding farmers owning less than 1 ha of farm land comprise about than 86 % of total land holdings. The large size equipment and prime movers are neither technically suitable nor economically affordable for small farms. In order to bridge the mechanization gap of small and marginal land holdings, an integral power equipment was designed. The design involves three-wheel riding type with single chassis for better stability and steerability. The equipment is having a single power source and the equipment is operated hydraulically like tractor. The power transmission system of the equipment is designed to have independent power tapping for linear and rotary power equipment. The tricycle system having steering and hydraulic mechanism like tractor and it consumes less energy (8 hp engine) compared with tractor and it also performs multiple field operations like shallow ploughing, inter culturing, weeding, sowing, rototilling, and irrigation water pumping.

- One power source multiple operations.

- Tri-wheel riding type equipment.

- Operated by 8 hp diesel engine.

- Hydraulic lifting of tillage equipment.

- Rotary and linear power tapping system.

- Less turning radius and better steerability.

- An appropriate technology for mechanization of small land holdings.

- Ownership feasibility for small and marginal farmers.

- Performs multiple field operations like shallow ploughing, interculturing, weeding, sowing and rototilling.

UAN cum Seed Applicator is a tractor drawn equipment designed for simultaneous UAN fertilizer application and seeding in cereal crops. The developed UAN applicator consists of precise UAN metering system, optimally designed furrow opener for precise placement of seed and UAN, seed box, UAN storage tanks and power transmission system. Pressurized UAN metering system consists of PTO operated piston pump and rotary distributor. A specially designed silt type furrow Opener to deliver the fertilizer vertically below the seed and also maintain distance between fertilizer and seed, is present in the developed UAN cum seed applicator. The silt type furrow opener results in seed placement at a depth of 2.5-3 cm from surface with UAN placed at about 4.5-5 cm from seed. The applicator can be operated by a commonly available 40-45 hp tractor and has average field capacity of 0.23 ha/h.

- The UAN cum seed applicator uniformly distributes UAN and its precise placement in furrow at optimum spacing from seed avoids seed damage and enhances nutrient use efficiency.

- The special slit type furrow opener delivers the UAN vertically below the seed and also maintains distance between UAN fertilizer and seed.

- To maintain uniform pressure and uniformity of flow, a circular rotary distributor is incorporated in the metering system.

- Facilitates simultaneous Urea Ammonium Nitrate liquid fertilizer application and seeding in cereal crops.

- The developed UAN cum seed applicator facilitates UAN delivery, soil cover and seed placement sequentially.

- The applicator is tractor drawn and helps in placement of UAN and seed simultaneously at pre-determined depths thereby, maintaining proper horizontal and vertical spacing between the two resulting in improved crop stand establishment and increased productivity.

- With the use of UAN , 30% saving in Nitrogen fertilizer could be attained compared to prilled urea application in paddy-wheat cropping system.

Working above head height and front horizontal distances increases physiological and postural stresses resulting in reduced efficiency. Greenhouse operations like pruning and harvesting are done at overhead height by the use of the existing system, which results in greater muscle loading, increased level of discomfort, a reduced performance due to restrictions on posture, difficulty in moving the system forward and backward, no height adjustment and are unsafe. The developed platform can be used in greenhouse pruning and harvesting operations. The developed equipment is battery operated with a facility of work height adjustment with a hydraulic power pack with a provision of forward and reverse movement. The telescopic steering also facilitates easy turning and control.

- Self-propelled adjustable platform for green houses.

- Can be used for Different Operations in greenhouses at different work heights.

- Operator can actuate the hydraulic pump or with a power pack for easy control of desired height with scissor arrangement.

- Self-propelled with battery power.

- Telescopic steering system.

- Differential system.

- Acceleration and braking with foot pedals.

- Max forward speed 20 km/hr.

- Max. Reverse speed :15km/h, Max. Lifting capacity: 120 kg, Turning radius:200 cm, Safe, easy to operate and very convenient to work at different heights, reduce drudgery, can be used for haulage.

- Battery pack can be used for auxiliary power supply.

- Battery operated variable height platform for working above shoulder heights.

- One unit is sufficient 2000 m2 greenhouse area.

- Self-propelled with battery power.

- Telescopic steering system Weight of the machine: 300 kg Dimensions(LXWXH): 1800x900x650 mm Height of platform: 1100 mm (lifted max.) Wheelbase: 135, cm BLDC motor :800 W, 48 V Transmission: Power transmission from motor to differential Lifting: Foot pedal operated /power pack for hydraulic pump and single-acting cylinder.

- Multipurpose use, Enhance work efficiency and capacity, Reduce drudgery, Can be converted to multi-tool carrier.

A manual multi-crop planter is developed for the sowing of vegetable crops. The planter is suitable for small fields, greenhouses, experimental plots, and nursery raising. The planter comprised of seed hopper, seed metering unit, drive roller, seed cover, press roller, furrow opener with depth adjustment, and a handle with height adjustment. The seed metering unit can be used for multiple types of crop seed by changing the seed plate. The metering unit also has provision for cleaning and a seed-knocking system for proper working. The depth of the sowing is adjustable up to 8 cm. A long handle is provided with height adjustment. The hopper can store 2-3 kg of seeds. Three different speeds of seed metering unit can be obtained by changing the sprockets.

- The hopper can store 2-3 kg of seeds.

- 1-2 persons required to operate.

- Depth of planting can be adjusted up to 8 cm.

- Number of seed metering disc are provided for different type of crop seed.

- Knockout system for clogged seed inside the seed metering unit.

- Seed cover provided to cover the seed.

- Handle height can be adjusted.

- Seed metering roller speed can be changed by interchanging the sprockets

- For sowing of vegetable seeds.

- For sowing of cereal and pulse crop seeds.

- For use in small field/ experimental plot.

- Suitable to NEH farmers.

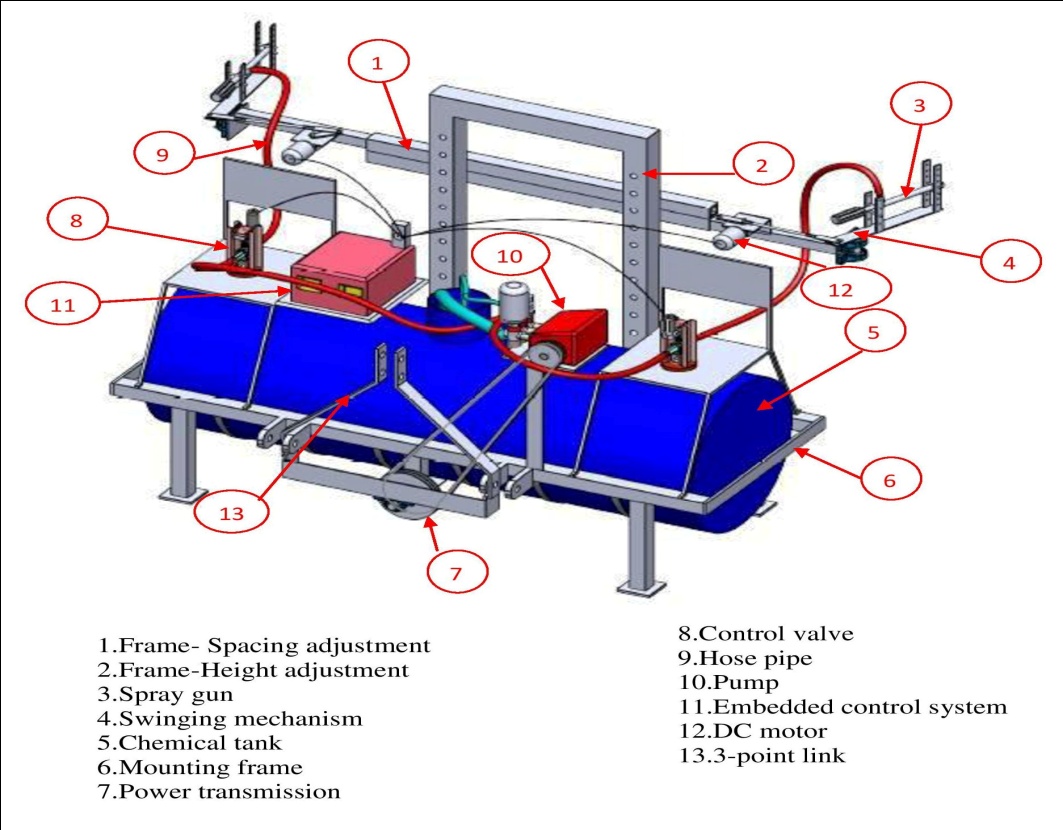

The precision swinging lance sprayer consisted of swinging lance sprayer, Embedded control unit (ECU), forward speed sensor and four bar mechanism, Regulate the chemical flow rate proportional to tractor forward speed

- Application rate, L ha-1,: 500

- Effective field capacity, ha.h-1: 3

- Bio-efficiency,%: 80%

- Forward speed, km h-1: 2.5-3

- The cost of operation ?.h-1.: 253

- Saving of chemical to the tune of 44.1% and man-hours 75% over tractor operated gun sprayer in addition to elimination of risk of human exposure to harmful chemicals.

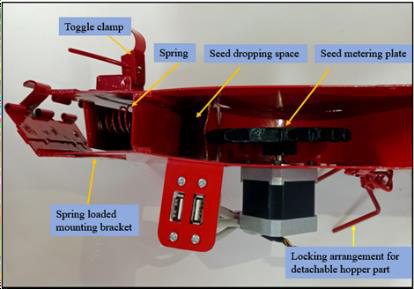

A mechanism was developed on the principle that Rotary Encoder senses the forward speed and transmits signals in digital code to the microcontroller. The microcontroller synchronizes the forward speed of the tractor into desired transmission ratio with the metering mechanism. The microcontroller transmits signals to the motor driver module and driver connected to the stepper motor, rotating the seed metering plate. The driver module can change the speed ratio between the ground wheel and the motor rotating the seed metering plate. The individual metering module is fitted with a retrofit mechanism that can be easily mounted cultivator tyne.

- Innovations:

- Accurate metering even with tractor slip/skid.

- Sensors determine the relationship between the tractor speed and the rotational speed of metering-device, place the seeds as per desired geometry.

- Versatility of sowing variety of seeds at different crop geometry or simultaneous sowing of multiple crops.

- Modular system to be retrofitted on cultivator owned by most of the farmers so no additional cost.

- Low Cost ~ Rs 2000 per module.

- Modular system, easy to install and easy to uninstall.

- Low maintenance cost being modular with less number of rotating parts.

- Only the faulted module needs to be repaired or replaced.

- Very low power consumption.

- Stand-alone power system for individual module.

The developed PUSA-ESMM is a low-cost retrofit with the cultivator. It can work as a multi-crop precision planting machine. It can be retrofitted and removed very easily with a developed mechanism for the varying sizes of strands of cultivators. The retrofitting with a lock ensures firm integration with cultivator tyne, sustaining the jerks, vibrations and obstacles encountered on the field without affecting the performance. The split hopper and metering system facilitates easy carrying and storage. There is no need for an additional power source as it is powered by tractor battery.

Pre-germinated paddy seeder facilitates sowing of pre-germinated paddy seed in puddled field maintaining proper row to row spacing. It can be operated by 2-3 persons, covering 0.2-0.4 ha/day. It reduces the cost of transplanting and also helps in subsequent operation of weeding and inter-cultivation.

It is made of two wheels and indented roller metering mechanism made up of Nylon rollers.

Pusa Pre-germinated Paddy Seeder is available in two forms – three and six rows with per day field capacity of 0.2 ha and 0.4 ha, respectively.

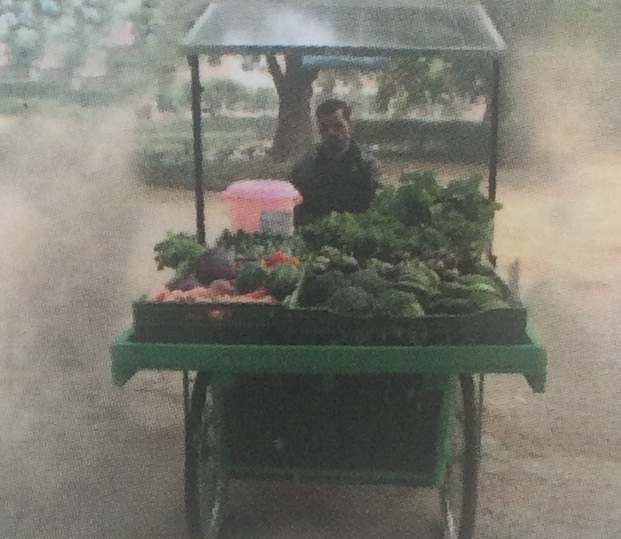

The mobile vending Cart has been developed to store fresh fruits and vegetables safely for 2-5 days. It Preserves fresh fruits and vegetables by controlling the environment around them and has provision of an additional storage space of 8.0 cubic feet, below the main platform.

It has solar power operated evaporative cooling system. Provided with an effective and uniform evaporative cooling arrangement with forced air circulation by DC fans and lighting facility through DC LED light powered by Solar Photo Voltaic (SPV) Panel of 100 Wp.

Equipped with a portable energy bank of 7Ah with the SPV through charge controller and protection devices to meet energy requirement of any additional low power rating domestic gadgets.

It is also provided with the fine misting system to maintain humidity inside the chamber which will keep the produce fresh.

It is capable of reducing temperature of storage chamber by 5-8°C and increase in relative humidity by 15 to 30 percent points. Thus, enhances storage life of fresh fruits

It maintains freshness of the produce in terms of color, texture and coars appearance up to five days which fetches more net income.

Useful in winter season also when ambient condition is dry which induces deterioration in appearance of the fresh vegetables.

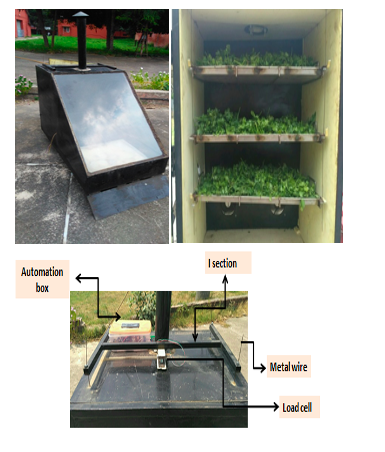

The Farm SunFridge- an off-grid, battery less solar refrigerated and evaporative cooled (SREC) structure has is of internal size 3 m x 3 m x 3 m and has a storage capacity of 2 metric tons of fruits and vegetables and can be used for storage of perishables by smallholder farmers. Two SREC designs were built with frames of concrete (c-SREC) and iron (i-SREC) and evaluated for their ability to regulate temperature and humidity. The temperature inside Farm SunFridge is 3-5 degree C during daytime, 8-10 degree C during nighttime, when the ambient is 35-45 °C, The RH inside Farm SunFridge is high around 85-95 %. The shelf life of produce increased by 4 times for produce (amaranth leaves, mangoes, tomatoes and potatoes) stored in Farm SunFridge. The Farm Sun Fridges were constructed and are being used in the Northern part of India.

The salient features include several innovative features that have been incorporated in the Farm Sunfridge including a “water battery” (a thermal reservoir) to provide nighttime cooling, a dual-use refrigeration coil to cool the thermal reservoir and interior air simultaneously, and a solar adaptive controller to regulate power demand by refrigeration compressor based on available solar energy.

Millions of smallholder farmers would benefit from having cold stores for keeping perishables after harvest until they are marketed. Cooling is essential to prevent decay, reduce senescence, enhance the marketable shelf life of the produce, and improve control over marketing. Cold stores need uninterrupted electricity supply. Further, they require a large initial capital investment and incur significant running costs. In India, the cold storages are typically situated near cities, far from rural production areas and many of these cold stores are commodity specific. Therefore, the farmers often end up selling their produce in nearby markets with little or no control over prices. On the other hand, their ability to hold produce for some period prior to sale would spread the marketing and risk, and thus maximize their returns. The SREC structure is beneficial for perishables storage by smallholder farmers and farmer organizations.

It consists of a microcontroller-based system to regulate the drying rate to help continuous and uniform drying resulting in better product. Use of phase change material as thermal energy storage will provide continuous and uniform drying of herbs and spices for prolonged hours even after sunset resulting in better quality product.

It provides controlled environment for drying of herbs at low temperature in order to preserve the flavour and colour. In hybrid dryer both thermal and photovoltaic energy of the sun is used to operate the dryer. The developed solar dryer provides a promising alternative for continuous drying of herbs even after sunshine hours with real time data acquisition system and also found to be superior in retaining quality.

The precision direct paddy seeder is useful technology for direct seeding of paddy crop avoiding the need for raising nursery. This results in saving of seed, labour, fertilizer and water compared to transplanting. The developed seeder precisely plants long grain basmati paddy seeds in rows. Inclined plates with cells along with modular hoppers are used for metering of paddy seeds. On an average a saving of 12 %, in seed rate was observed with this technology.

- Power Source: 45 hp tractor.

- Metering system: Inclined plate type.

- Field Capacity: 0.27 ha/h.

- Number of furrow openers (planting rows): 9, Row to row spacing: 20 cm.

- Precision planting of paddy seeds in DSR method (2-3 seeds per hill) @ 20 kg/ha seed rate.

- Planting of paddy with less seed rate, precise plant spacing and without need for nursery raising.

- A saving of 12%, in seed rate, 18 % in irrigation water, and 15-25% labour saving by sowing with precision paddy planter compared to transplanted paddy.

Application of aqueous fertilizer alongside the seed which helps in better germination and initial development of crop specially in rain fed conditions. It can be operated with 45 hp tractor and can cover an area of 0.25 ha/h. It has fluted roller seed metering mechanism, two liquid fertilizer storage tank with constant head central tank along with rotary pump connecting discharge nozzles.

It makes possible sowing of Rabi crops in dry land areas. Also suitable for pulses. A 53% increase in germination and 35% increase in yield in wheat crop

Precise and Mechanical application of hydrogel at the rate of 3kg/ha along with seed . It can be retrofitted with existing sowing system.It has helical fluted roller metering mechanism.

Hydrogel absorbs water 350 times of its dry weight and slowly made available to plants roots during stress condition. The applicator is an attachment to the seed � cum ferti seed drill or aqua ferti. seed drill

Suitable for protecting injuries caused by chaff cutter. Simple cost effective interventions. It consists of Blade Guard,Flywheel, Lock and Warning Roller.

These can be retrofitted on existing as well as new machines for prevention of injuries.

Useful for spraying pesticides and weedicides on the field crops. Powered with Solar power 24 V chargeable battery. It consists of three head boom, solar charging system and anti-nozzle clogging filter. Field capacity is0.5 ha per hour with swath of 1.7 m.

It has high chemical efficacy and uniform droplet size (150 to 200 micron).It reduces human drudgery, saves25 % in cost of operation and 30 % in labour and operating time

Keeps vegetable fresh and increases shelf life. Reduces the temperature in the range of 4 to 10 oC on an average 7oC.Powered with 48 V 400 Wp solar panel. It has a storage capacity of 8 cu ft

Very useful in rural areas where there is shortage of electricity for storage of fresh vegetables.

It is an improved manual tool used for weeding and inter-culture in row crops. It can cover an area of 200 sq m in an hour. It comprises of a wheel, an adjustable handle and soil working tool .

The angle of operation could be adjusted according to stature of the operator, reduces operator fatigue. Cost effective for weeding and inter-culture operation

Useful machine for cleaning/separation of chaff, dust from food grains, powered by 1 hp Single-phase motor, capacity 300-600 kg/h .

It is useful handy machine for on farm value addition. It is very economical in operational use.

Phone

Phone